Products

Steel Shearing Machine

Product Details

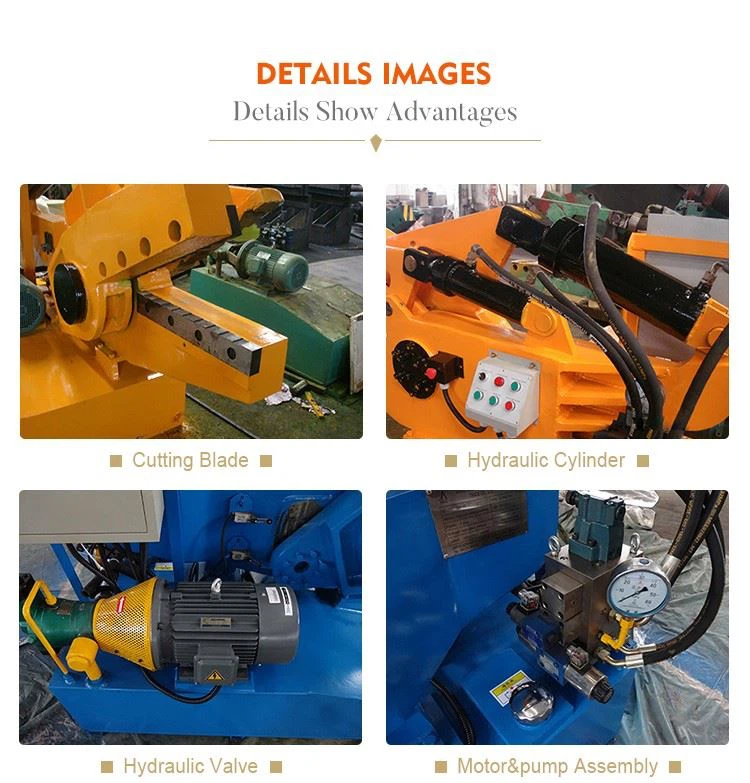

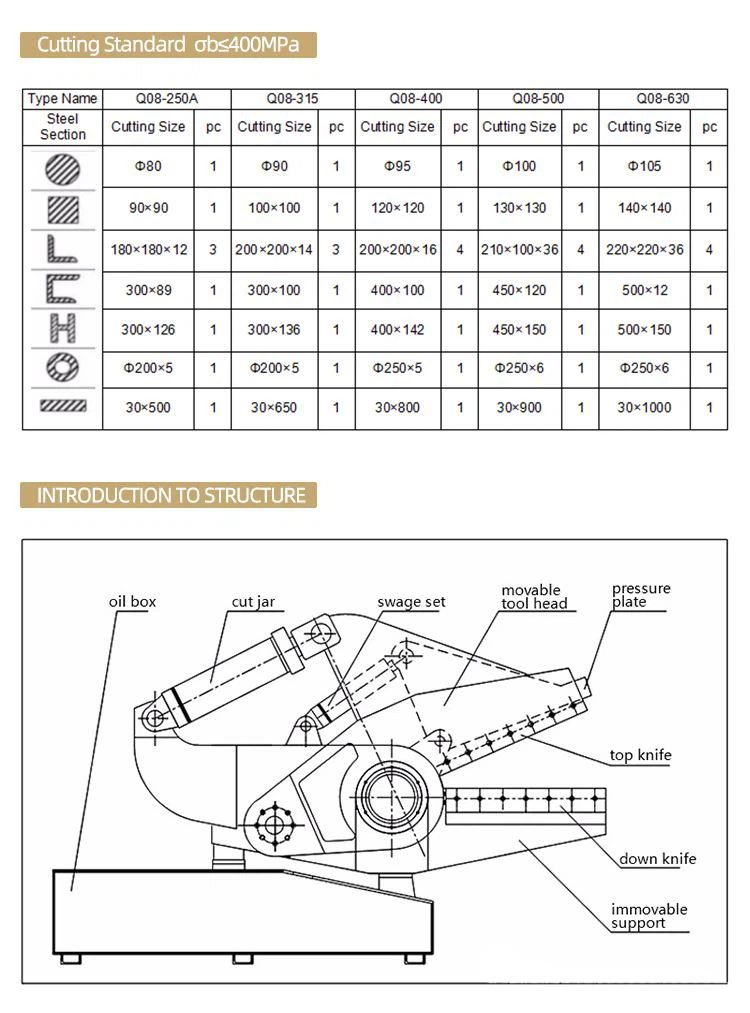

Hydraulic shearing machine is the important role they play among metal recyclers, enable shredders to handle oversized material that would otherwise be difficult and sometimes impossible to digest by cutting items down to size - literally Digestion. Hydraulic shearing machine Shred by removing unwanted accessories or other parts that the shredder may not accept.

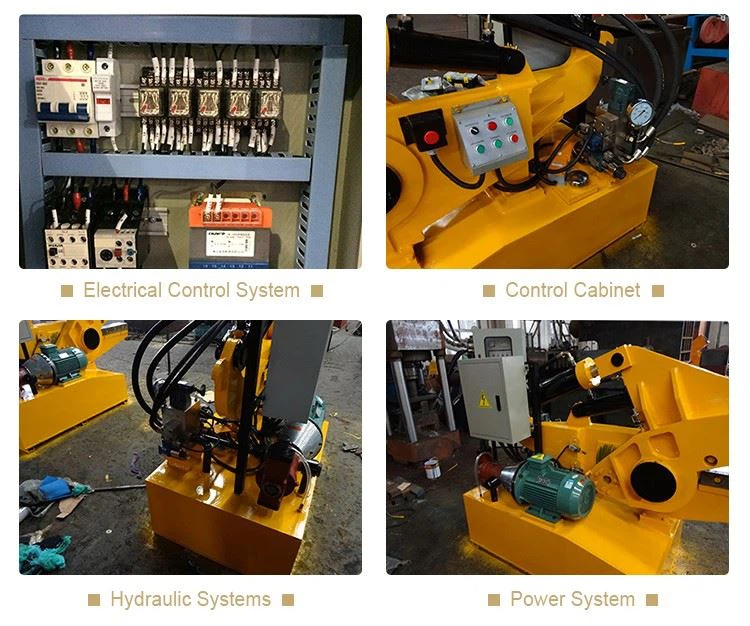

Product Parmeters

| Condition: | New | Product Name: | Waste Metal Sheet Shears |

| Place of Origin: | Jiangsu, China | Voltage: | optional |

| Dimension(L*W*H): | Difference | Certification: | CE |

| Year: | 2023 | Warranty: | one year all life supporting |

| Rated Power: | 22kw | Weight: | 160t |

| Max.cutting Force: | 1000ton | Blade length: | 600mm |

| Max.cutting Size: | 30*200 mm | Shearing Frequency: | 12-20times/min |

| Motor: | 7.5kw | System: | Hydraulic |

Product Show

Why need the machine

Hydraulic shearing machines are an essential tool in the metalworking industry. They provide precise cutting of various materials including steel, aluminum, and copper. The machines are designed with a hydraulic pump that supplies the pressure needed for cutting. The cutting force of the machine is adjustable, which allows the operator to work with different materials.

How to maintain

1. Keep it clean: Regularly clean the shear and its blades to prevent buildup of dirt and debris. Use a cleaning solution and a soft brush to remove any buildup, especially in areas where metal shavings tend to accumulate.

2. Check the blades: Check the blades for any damage or signs of dullness. If you notice any chips, cracks or dullness, it is important to sharpen or replace the blades as soon as possible. Dull blades not only reduce the quality of the cut, but can also cause damage to the shear itself.

3. Lubricate regularly: Use a lubricant on the moving parts of the shear to reduce friction and reduce wear and tear. This can prolong the life of the shear and prevent any unnecessary repairs.

4. Check the hydraulic system: If your shear is hydraulic, regularly check the fluid levels and change the hydraulic oil as recommended by the manufacturer. Proper maintenance of the hydraulic system can prevent leaks and other malfunctions.

5. Store properly: When not in use, it is important to store your metal shear properly. Keep it in a dry and secure location to prevent rust and damage from moisture.

Why choose us

Sale Service

1.Acceptance equipment together with you.

2.Help you to make the method statement and the details of the process.

After Service

1.Guarantee for a year.

2.Quality problemof hyfraulic shearing machine,we will send you the accessories.

3.Free repair whole using life(without the freight and accessories charge).

Hot Tags: steel shearing machine, factory, customized, cheap, low price, Guillotine Shear For Rubbish Tube Copper, Most Effective Metal Cutting Scissor, Steel Plate Shearing Machine, Leftover Tyre Cutting Machine, 60cm Blade Cutting Machine For Angle Iron, Scrap Nickel Plate Cutting Cutter Machine